Some Terms & Definitions

| robot | The entire vehicle, combining rover and applicator. |

| module | A self contained collection of hardware and software that can be viewed as a single component, e.g. a wheel module |

| rover | The chassis, a frame with wheels. That part of the robot responsible for driving the robot around. This includes all electrics/electronics/software to enable that. |

| applicator | That part of the robot responsible for doing the task it's designed to carry out, e.g. a weed control/removal module |

Automated Field Vehicle "The ISF Rover"

The vehicle has a modular design and consists of:

- 2 wheel modules

- 1 control module

- 1 electric weed control module

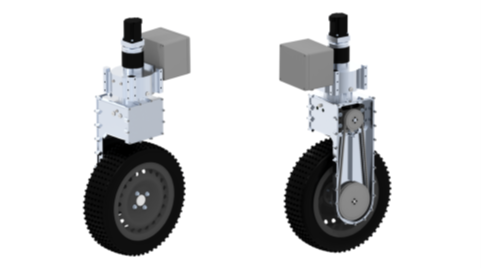

Wheel Module

Moving around is arguably the most fundamental ability a field robot needs. As such we started our development journey with inventing the wheel — a wheel module, that is.

This module allows for truly omnidirectional movement of a rover by incorporating both steering and driving into one module. As such it requires two motors: One to drive the wheel forward (or backward) and one to point the wheel in the right direction.

Two or more of these modules can work together to carry any type of applicator to its destination.

Specifications:

- Weight ~ 60 kg

- Payload ~ 150 kg

- Electric voltage 48 V

- Electric current 46 A (nominal)

- Torque Drive Power 240 Nm (nominal), 283 Nm (max) 1.0 kW

- Torque Turn Power 112 Nm (nominal), 263 Nm (max) 0.75 kW

- Speed 1.0 m/s ( 3.6 km/h)

- Steering angle 270° (+/-135°)

- Actual material costs Ca. 12’000 CHF (batch size: 2 pcs)

Control Module

This is the brains of the operation and the interface the rover and the application built on top.

At its core is a single board computer running a real-time Linux kernel. Atop the kernel sit EEROS and ROS2 giving the rover its smarts.

On the hardware side it boasts a CAN bus for the wheel modules and GNSS-RTK receiver with two antennas for global positioning.

This is a work in progress. The control software is different for each rover and as such lives in the respective rover's software repository. See, for example, the aptly named example rover.

Electric Weed Control

Eliminate Weeds with precision and without chemicals using the power of electricity! This is one of the first applications built with the Open Field Automation in mind.

Electric impulses of 30 kV are used to control weeds. Each weed is treated individually, making it a great technology for use in in combination with mulch.

Fun as it may be to zap weeds with lightning, doing so manually gets tedious quickly. An ideal use case for some field automation! Using a easily configurable and open source chassis to carry it.

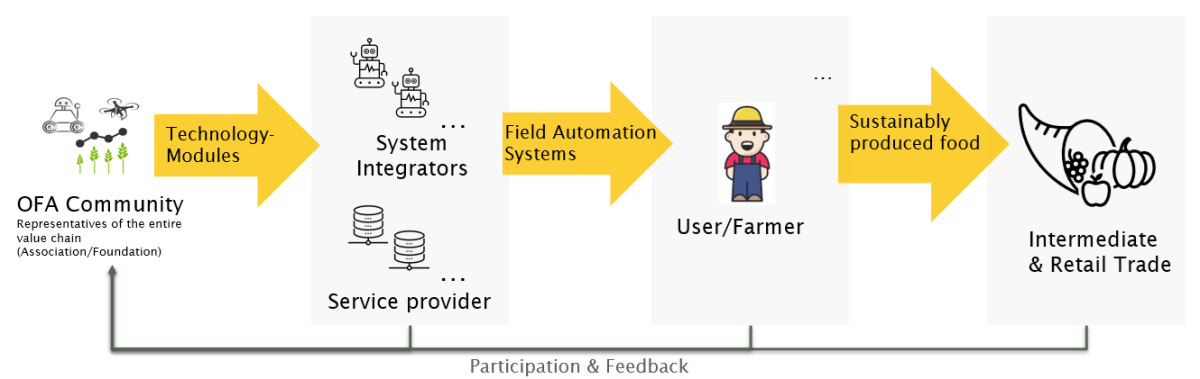

Organisation / Collaboration

The Open Farming Platform is built on collaboration.

The OFA community provides technology modules to suppliers of agricultural technology or other universities. These suppliers provide complete systems to farmers (including services and warranty). This enables farmers are to sell more sustainable products to the retail business. All players of the value chain are integrated into the OFA community.